- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

C-color

MATALE

| Availability: | |

|---|---|

Parameters

Machine size(L*W*H):5500*1500*3000(2m) 7700*1500*3000(4m)

Working width:2m or 4m

M/C gauge:5/32",1/8",1/10",1/12"M-color Plus

Main structure:cast frame and six position foot screw ensure machine stability

Total power ref.:45KW(2m)60KW(4m)

Mechanical speed:800-1000 RPM

Pile height:2.5-9 mm

Stitch rate:25-50 stitches /10cm

Primary back loading:cylinder automatic control

Primary back fabric feeding:double servo motor control

Gauge parts:Groz Germany

Adjustable bed plate:flexible manual control.

Standard power cabinet and operation cabinet with 12.5"touch screen

Industrial computer with latest windows system

Puller roller:servo motor control

Sliding:single needle bar with servo motor control

Yarn feeding:individual servo motor control

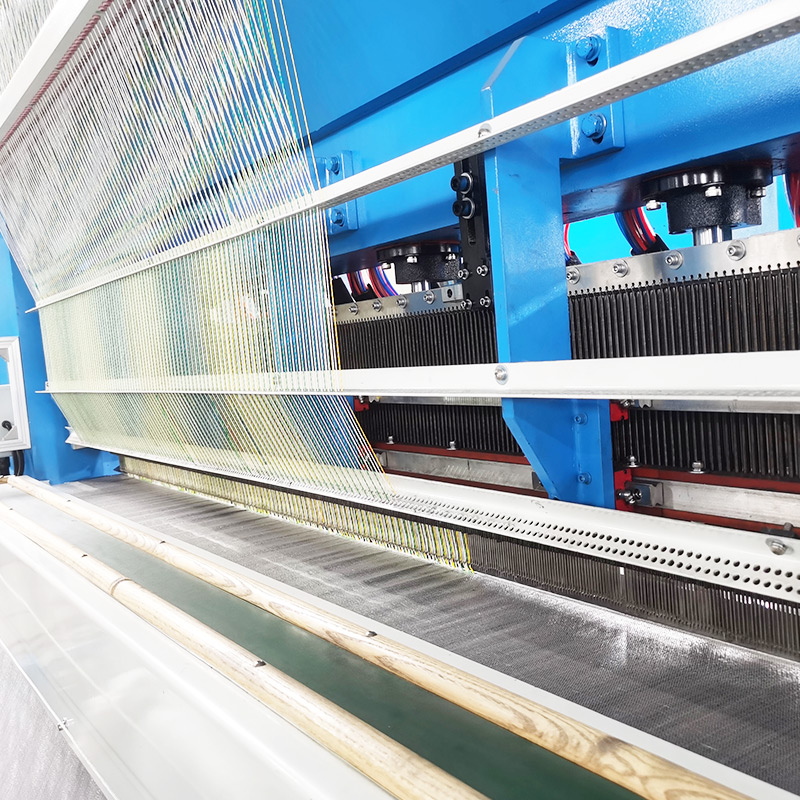

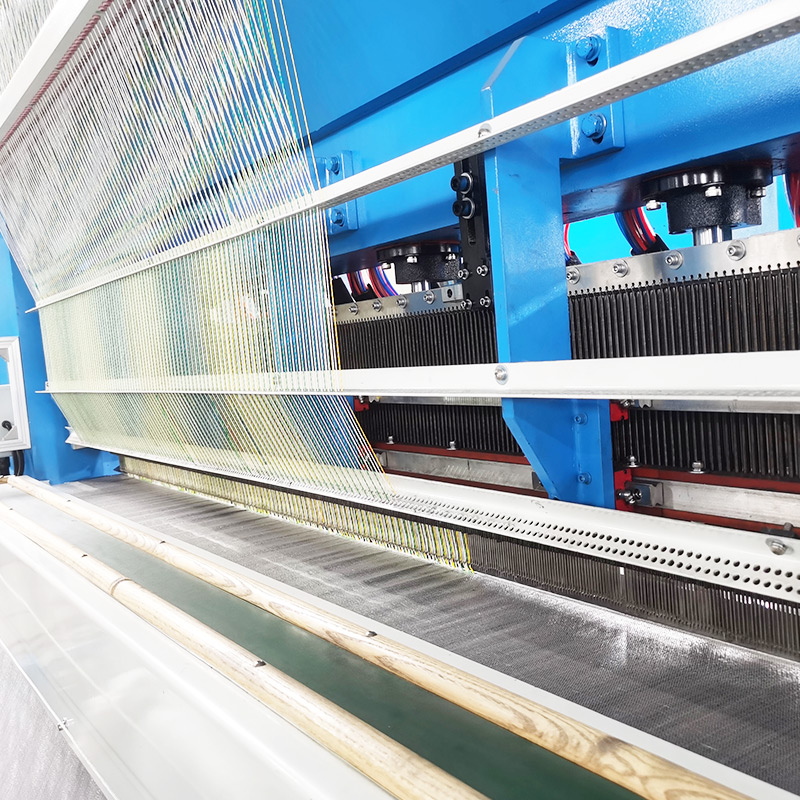

Multi Color Tufting Machine Product photos

|  |  |  |  |  |  |

Machine Feature

Stable structure with no internal stress

deformation by using cast frame and overall annealing treatment.

Needle beam driver adopts 70mm modulating shaft, with gear meshing balance shaft.

Equipped with lifting rings , easy for movement.

Air cylinder device for backing roll loading.

High configuration of mechanical parts like SKF bearing, Groz gauge part s etc .

By using 4 individual point s crews , machine can stand on all types of floors.

Equipped with Touch screen, Siemens PLC , individual power and computer cabinet.

Overload protection, cover protections , pull wire emergency stop switch.

Servo control backing feeding, planetary reducer control of machine driving makes machine running with big torque stably.

Multi Color Tufting Machine Details

|  |  |

|  |  |

Video

| | | |

Company

WUXI MATALE INDUSTRY&TECH CO.,LTD IS PROFESSIONAL DESIGNING AND MANUFACTORY OF CARPET TUFTING AND BACK COATING MACHINES IN CHINA.

WITH MANY YEARS EXPERIENCE OF SALES IN CHINA AND ABROAD, OUR MACHINES WON BIG MARKET SHARE AND GOOD REPUTATION. COMMOTTED TO THE RESEARCH AND DEVELOPMENT OF ALL KINDS OF TUFTING MACHINE AND ANCILLARY EQUIPMENT, NOW MATALE HAS FULL RANGE OF TUFTING MACHINES, INCLUDING CUT AND LOOP PILE SERIES, MULTI-LOOP SERIES, FRS SERIES AND MULTI-NEEDLE ICN SERIES ETC.

OUR MACHINES ARE WIDELY USED FOR CAR- PET TILES, WALL TO WALL CARPET, PRINT CARPET, AREA RUGS , BATH MAT, DOOR MAT AND ARTIFICIAL GRASS ETC.

WE HOPE TO CREATE A BRIGHT FUTURE WITH FRIENDS FROM ALLOVER THE WORLD.

|  |  |

Service

Pre-sale service

Free inquiry

Professional suggestion on tufting machine model choosing

Full procedure solutions to establish a new carpet/rug factory

Machine photos and video

A formal offer

After-sale service

Video technical support

Online support

Free spare parts

Field installation, commissioning and training

Field maintenance and repair service

Whole-life service

Video technical support

Online support

Spare parts under compensation

Field maintenance and repair service under compensation

Packing and shipping

Packing details

1. Wrapping film with steel wire fixed for main machine

2. Wooden case or carton for small parts packing.

Shipping details

1. Test running before shipping

2. Strictly inner inspection before loading

3. Loading photos or videos provided

FAQ

Q 1: Payment terms capacity?

A 1: T/T, L/C, Western Union etc.

Q 2: Trade terms?

A 2: In according with Incoterms 2010, normally with EXW, FOB shanghai, CFR, CIP, CIF and DDU.

Q 3: Validity of quotation?

A 3: Within 30 days.

Q 4: Modes of shipment?

A 4: By sea or railway.

Q 5: Warranty?

A 5: One year. Will offer after sell service in whole life of machine use under compensation after one year.

Q 6: Installation and training?

A 6: There is technical and installation support in India. Other countries, paid overseas engineering service provided.

Parameters

Machine size(L*W*H):5500*1500*3000(2m) 7700*1500*3000(4m)

Working width:2m or 4m

M/C gauge:5/32",1/8",1/10",1/12"M-color Plus

Main structure:cast frame and six position foot screw ensure machine stability

Total power ref.:45KW(2m)60KW(4m)

Mechanical speed:800-1000 RPM

Pile height:2.5-9 mm

Stitch rate:25-50 stitches /10cm

Primary back loading:cylinder automatic control

Primary back fabric feeding:double servo motor control

Gauge parts:Groz Germany

Adjustable bed plate:flexible manual control.

Standard power cabinet and operation cabinet with 12.5"touch screen

Industrial computer with latest windows system

Puller roller:servo motor control

Sliding:single needle bar with servo motor control

Yarn feeding:individual servo motor control

Multi Color Tufting Machine Product photos

|  |  |  |  |  |  |

Machine Feature

Stable structure with no internal stress

deformation by using cast frame and overall annealing treatment.

Needle beam driver adopts 70mm modulating shaft, with gear meshing balance shaft.

Equipped with lifting rings , easy for movement.

Air cylinder device for backing roll loading.

High configuration of mechanical parts like SKF bearing, Groz gauge part s etc .

By using 4 individual point s crews , machine can stand on all types of floors.

Equipped with Touch screen, Siemens PLC , individual power and computer cabinet.

Overload protection, cover protections , pull wire emergency stop switch.

Servo control backing feeding, planetary reducer control of machine driving makes machine running with big torque stably.

Multi Color Tufting Machine Details

|  |  |

|  |  |

Video

| | | |

Company

WUXI MATALE INDUSTRY&TECH CO.,LTD IS PROFESSIONAL DESIGNING AND MANUFACTORY OF CARPET TUFTING AND BACK COATING MACHINES IN CHINA.

WITH MANY YEARS EXPERIENCE OF SALES IN CHINA AND ABROAD, OUR MACHINES WON BIG MARKET SHARE AND GOOD REPUTATION. COMMOTTED TO THE RESEARCH AND DEVELOPMENT OF ALL KINDS OF TUFTING MACHINE AND ANCILLARY EQUIPMENT, NOW MATALE HAS FULL RANGE OF TUFTING MACHINES, INCLUDING CUT AND LOOP PILE SERIES, MULTI-LOOP SERIES, FRS SERIES AND MULTI-NEEDLE ICN SERIES ETC.

OUR MACHINES ARE WIDELY USED FOR CAR- PET TILES, WALL TO WALL CARPET, PRINT CARPET, AREA RUGS , BATH MAT, DOOR MAT AND ARTIFICIAL GRASS ETC.

WE HOPE TO CREATE A BRIGHT FUTURE WITH FRIENDS FROM ALLOVER THE WORLD.

|  |  |

Service

Pre-sale service

Free inquiry

Professional suggestion on tufting machine model choosing

Full procedure solutions to establish a new carpet/rug factory

Machine photos and video

A formal offer

After-sale service

Video technical support

Online support

Free spare parts

Field installation, commissioning and training

Field maintenance and repair service

Whole-life service

Video technical support

Online support

Spare parts under compensation

Field maintenance and repair service under compensation

Packing and shipping

Packing details

1. Wrapping film with steel wire fixed for main machine

2. Wooden case or carton for small parts packing.

Shipping details

1. Test running before shipping

2. Strictly inner inspection before loading

3. Loading photos or videos provided

FAQ

Q 1: Payment terms capacity?

A 1: T/T, L/C, Western Union etc.

Q 2: Trade terms?

A 2: In according with Incoterms 2010, normally with EXW, FOB shanghai, CFR, CIP, CIF and DDU.

Q 3: Validity of quotation?

A 3: Within 30 days.

Q 4: Modes of shipment?

A 4: By sea or railway.

Q 5: Warranty?

A 5: One year. Will offer after sell service in whole life of machine use under compensation after one year.

Q 6: Installation and training?

A 6: There is technical and installation support in India. Other countries, paid overseas engineering service provided.