- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

8+4

MATALE

| Availability: | |

|---|---|

Patterned loop pile tufting machine Parameters

1. Machine size(L*W*H):6200*2200*2800(2m)8200*2200*2800(4m)

2. Working width:2m or 4m

3. M/C gauge:1/12,1/8(one servo feed)+1/4(individual yarn control)

4. Main structure:cast frame and six position foot screw ensure machine stability

5. Total power ref.:40KW(2m)55KW(4m)

6. Mechanical speed:1000 RPM

7. Pile height:2.5-9 mm

8. Stitch rate:25-60 stitches /10cm

9. Primary back roller loading:cylinder automatic control

10. Primary back fabric feeding:double servo motor control

11. Gauge parts:both Groz and China made available.

12. Adjustable bed plate:flexible manual control.

13. Standard power cabinet and operation cabinet with 12.5"touch screen

14. Industrial computer with latest windows system

15. Puller roller:servo motor control

16. Sliding:double needle bar with servo motor control

17. Yarn feeding:1/4 individual servo motor control,1/8 one servo motor control

18. roller feeding

Machine Feature

Stable structure with no internal stress

deformation by using cast frame and overall annealing treatment.

Needle beam driver adopts 70mm modulating shaft, with gear meshing balance shaft.

Equipped with lifting rings , easy for movement.

Air cylinder device for backing roll loading.

High configuration of mechanical parts like SKF bearing, Groz gauge part s etc .

By using 4 individual point s crews , machine can stand on all types of floors .

Equipped with Touch screen, Siemens PLC , individual power and computer cabinet.

Overload protection, cover protections , pull wire emergency stop switch.

Servo control backing feeding, planetary reducer control of machine driving makes machine running with big torque stably.

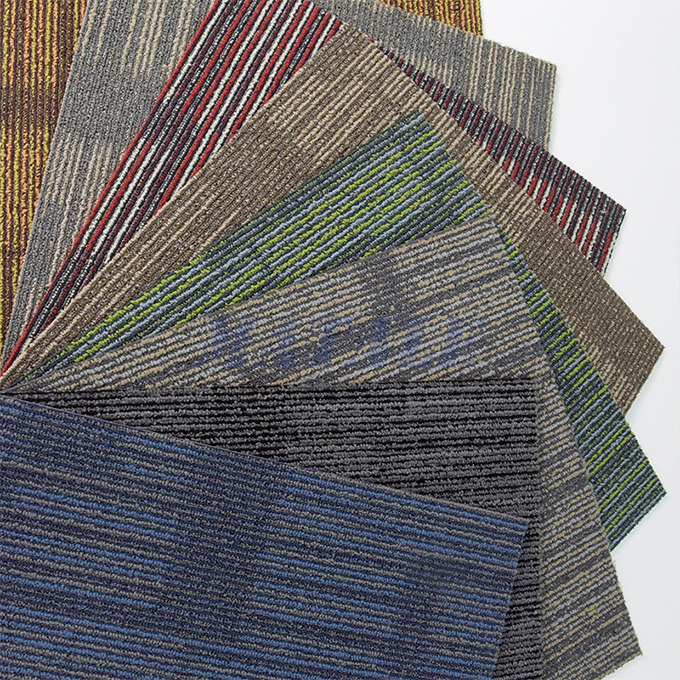

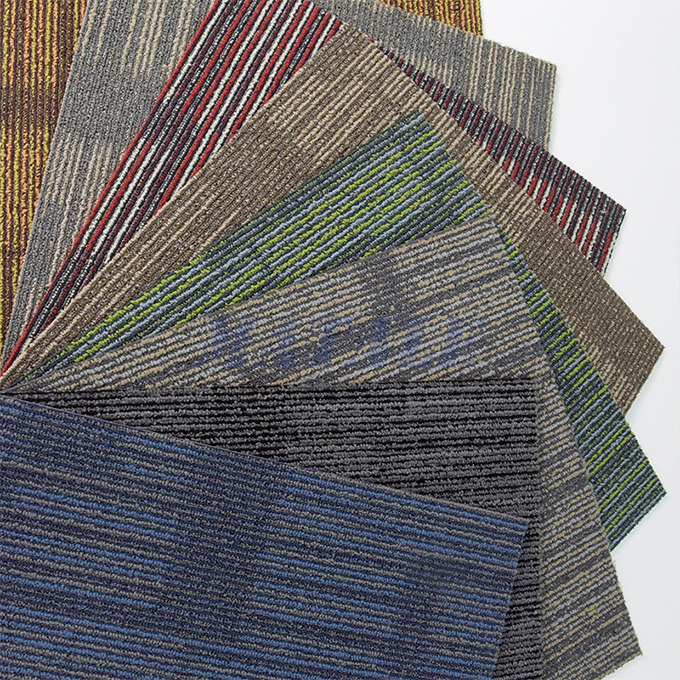

8+4 Tufting Machine Product

|  |  |

Shipping details

1. Test running before shipping

2. Unloading guidance will be provided after shipment.

3. Strictly inspection before loading at factory

4. Provide loading videos and photos of the goods during the shipment process.

FAQ

Q1: Can you design the production line according to our requirements?

A1: Yes, we can design the machine layout and provide the overall solution according to your factory size, annual required artificial grass output and target market, etc.

Q2: Can you install the machine in our local factory?

A2: Yes, we provide local installation service.

Q3: Can you provide guidance on artificial turf production?

A3: Yes, we provide technical guidance on machine use and production process, and can help train your workers.

Q 4: Modes of shipment?

A 4: By sea or railway.

Q 5: Warranty?

A 5: One year. Will offer after sell service in whole life of machine use under compensation after one year.

Patterned loop pile tufting machine Parameters

1. Machine size(L*W*H):6200*2200*2800(2m)8200*2200*2800(4m)

2. Working width:2m or 4m

3. M/C gauge:1/12,1/8(one servo feed)+1/4(individual yarn control)

4. Main structure:cast frame and six position foot screw ensure machine stability

5. Total power ref.:40KW(2m)55KW(4m)

6. Mechanical speed:1000 RPM

7. Pile height:2.5-9 mm

8. Stitch rate:25-60 stitches /10cm

9. Primary back roller loading:cylinder automatic control

10. Primary back fabric feeding:double servo motor control

11. Gauge parts:both Groz and China made available.

12. Adjustable bed plate:flexible manual control.

13. Standard power cabinet and operation cabinet with 12.5"touch screen

14. Industrial computer with latest windows system

15. Puller roller:servo motor control

16. Sliding:double needle bar with servo motor control

17. Yarn feeding:1/4 individual servo motor control,1/8 one servo motor control

18. roller feeding

Machine Feature

Stable structure with no internal stress

deformation by using cast frame and overall annealing treatment.

Needle beam driver adopts 70mm modulating shaft, with gear meshing balance shaft.

Equipped with lifting rings , easy for movement.

Air cylinder device for backing roll loading.

High configuration of mechanical parts like SKF bearing, Groz gauge part s etc .

By using 4 individual point s crews , machine can stand on all types of floors .

Equipped with Touch screen, Siemens PLC , individual power and computer cabinet.

Overload protection, cover protections , pull wire emergency stop switch.

Servo control backing feeding, planetary reducer control of machine driving makes machine running with big torque stably.

8+4 Tufting Machine Product

|  |  |

Shipping details

1. Test running before shipping

2. Unloading guidance will be provided after shipment.

3. Strictly inspection before loading at factory

4. Provide loading videos and photos of the goods during the shipment process.

FAQ

Q1: Can you design the production line according to our requirements?

A1: Yes, we can design the machine layout and provide the overall solution according to your factory size, annual required artificial grass output and target market, etc.

Q2: Can you install the machine in our local factory?

A2: Yes, we provide local installation service.

Q3: Can you provide guidance on artificial turf production?

A3: Yes, we provide technical guidance on machine use and production process, and can help train your workers.

Q 4: Modes of shipment?

A 4: By sea or railway.

Q 5: Warranty?

A 5: One year. Will offer after sell service in whole life of machine use under compensation after one year.