- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

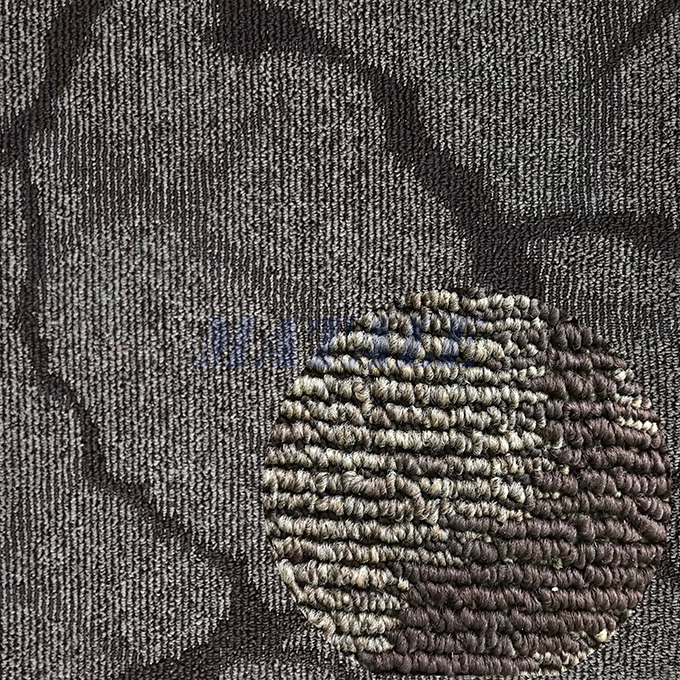

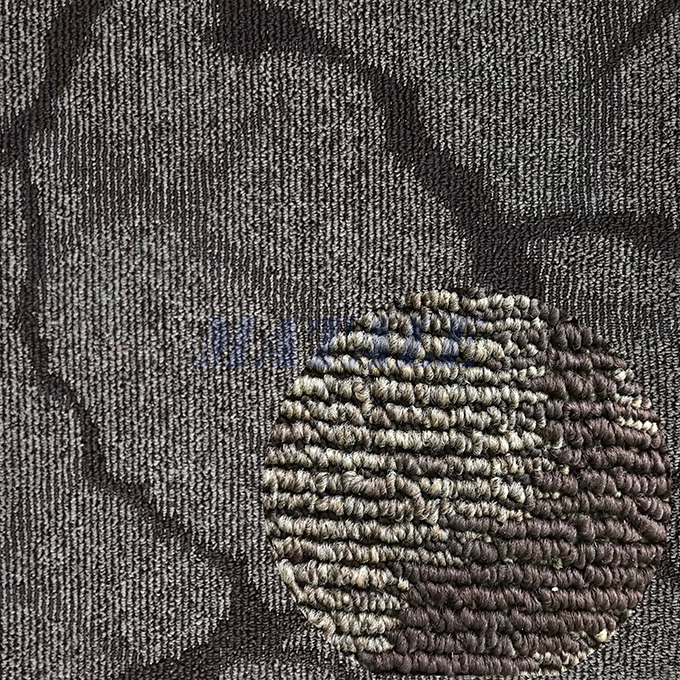

Organic

MATALE

| Availability: | |

|---|---|

Patterned loop pile tufting machine Parameters

1. Machine size (L*W*H):6200*2200*2800(2m) 8200*2200*2800(4m)

2. Working width:2m or 4m

3. M/C gauge:1/12,1/B(one servo feed)+1/4(individual yarn control)

4. Main structure:cast frame and six position foot screw ensure machine stability

5. Total power ref.:40KW(2m) 55KW(4m)

6. Mechanical speed:1000 RPM

7. Pile height:2.5-9 mm

8. Stitch rate:25-60 stitches /10cm

9. Primary back roller loading:cylinder automatic control

10. Primary back fabric feeding:double servo motor control

11. Gauge parts:both Groz and China made available.

12. Adjustable bed plate:flexible manual control

13. Standard power cabinet and operation cabinet with 12.5'touch screen

14. Industrial computer with latest windows system

15. Puller roller:servo motor control

16. Sliding:double needle bar with servo motor control

17. Yarn feeding:1/4 individual servo motor control,1/8 one servo motor control

roller feeding

Machine Feature

Stable structure with no internal stress

deformation by using cast frame and overall annealing treatment.

Needle beam driver adopts 70mm modulating shaft, with gear meshing balance shaft.

Equipped with lifting rings , easy for movement.

Air cylinder device for backing roll loading.

High configuration of mechanical parts like SKF bearing, Groz gauge part s etc .

By using 4 individual point s crews , machine can stand on all types of floors .

Equipped with Touch screen, Siemens PLC , individual power and computer cabinet.

Overload protection, cover protections , pull wire emergency stop switch.

Servo control backing feeding, planetary reducer control of machine driving makes machine running with big torque stably.

Organic Tufting machine Product

|  |

OTHERTERMS:

1. Shipping port: Shanghai

2. Origin: China

3. Price valid for 30 days

FAQ

Q 1: Q:How can i get to your factory?

A:Our factory is near shanghai Airport, we can pick you up in the airport .

Q 2: Trade terms?

A 2: In according with Incoterms 2010, normally with EXW, FOB shanghai, CFR, CIP, CIF and DDU.

Q 3: Validity of quotation?

A 3: Within 30 days.

Q 4: Modes of shipment?

A 4: By sea or railway.

Q 5: Warranty?

A 5: One year. Will offer after sell service in whole life of machine use under compensation after one year.

Q 6: Installation and training?

A 6: There is technical and installation support in India. Other countries, paid overseas engineering service provided.

Q7: why choose us?

First, we are professional carpet machinery designer and manufacture. We can provide whole production line for carpet making. Also provide spare parts service for the whole life.?

Second, our engineers are all skilled and full of experience. And management with ISO9001 quality system.?Always doing final Inspection?and test running before shipment.

Third, with advanced technical improvement, as one of the representative of China made tufting machine manufacture, our tufting machine achieves high level quality and perfect performance compared with top brand worldwide, but very competive price.?

Patterned loop pile tufting machine Parameters

1. Machine size (L*W*H):6200*2200*2800(2m) 8200*2200*2800(4m)

2. Working width:2m or 4m

3. M/C gauge:1/12,1/B(one servo feed)+1/4(individual yarn control)

4. Main structure:cast frame and six position foot screw ensure machine stability

5. Total power ref.:40KW(2m) 55KW(4m)

6. Mechanical speed:1000 RPM

7. Pile height:2.5-9 mm

8. Stitch rate:25-60 stitches /10cm

9. Primary back roller loading:cylinder automatic control

10. Primary back fabric feeding:double servo motor control

11. Gauge parts:both Groz and China made available.

12. Adjustable bed plate:flexible manual control

13. Standard power cabinet and operation cabinet with 12.5'touch screen

14. Industrial computer with latest windows system

15. Puller roller:servo motor control

16. Sliding:double needle bar with servo motor control

17. Yarn feeding:1/4 individual servo motor control,1/8 one servo motor control

roller feeding

Machine Feature

Stable structure with no internal stress

deformation by using cast frame and overall annealing treatment.

Needle beam driver adopts 70mm modulating shaft, with gear meshing balance shaft.

Equipped with lifting rings , easy for movement.

Air cylinder device for backing roll loading.

High configuration of mechanical parts like SKF bearing, Groz gauge part s etc .

By using 4 individual point s crews , machine can stand on all types of floors .

Equipped with Touch screen, Siemens PLC , individual power and computer cabinet.

Overload protection, cover protections , pull wire emergency stop switch.

Servo control backing feeding, planetary reducer control of machine driving makes machine running with big torque stably.

Organic Tufting machine Product

|  |

OTHERTERMS:

1. Shipping port: Shanghai

2. Origin: China

3. Price valid for 30 days

FAQ

Q 1: Q:How can i get to your factory?

A:Our factory is near shanghai Airport, we can pick you up in the airport .

Q 2: Trade terms?

A 2: In according with Incoterms 2010, normally with EXW, FOB shanghai, CFR, CIP, CIF and DDU.

Q 3: Validity of quotation?

A 3: Within 30 days.

Q 4: Modes of shipment?

A 4: By sea or railway.

Q 5: Warranty?

A 5: One year. Will offer after sell service in whole life of machine use under compensation after one year.

Q 6: Installation and training?

A 6: There is technical and installation support in India. Other countries, paid overseas engineering service provided.

Q7: why choose us?

First, we are professional carpet machinery designer and manufacture. We can provide whole production line for carpet making. Also provide spare parts service for the whole life.?

Second, our engineers are all skilled and full of experience. And management with ISO9001 quality system.?Always doing final Inspection?and test running before shipment.

Third, with advanced technical improvement, as one of the representative of China made tufting machine manufacture, our tufting machine achieves high level quality and perfect performance compared with top brand worldwide, but very competive price.?